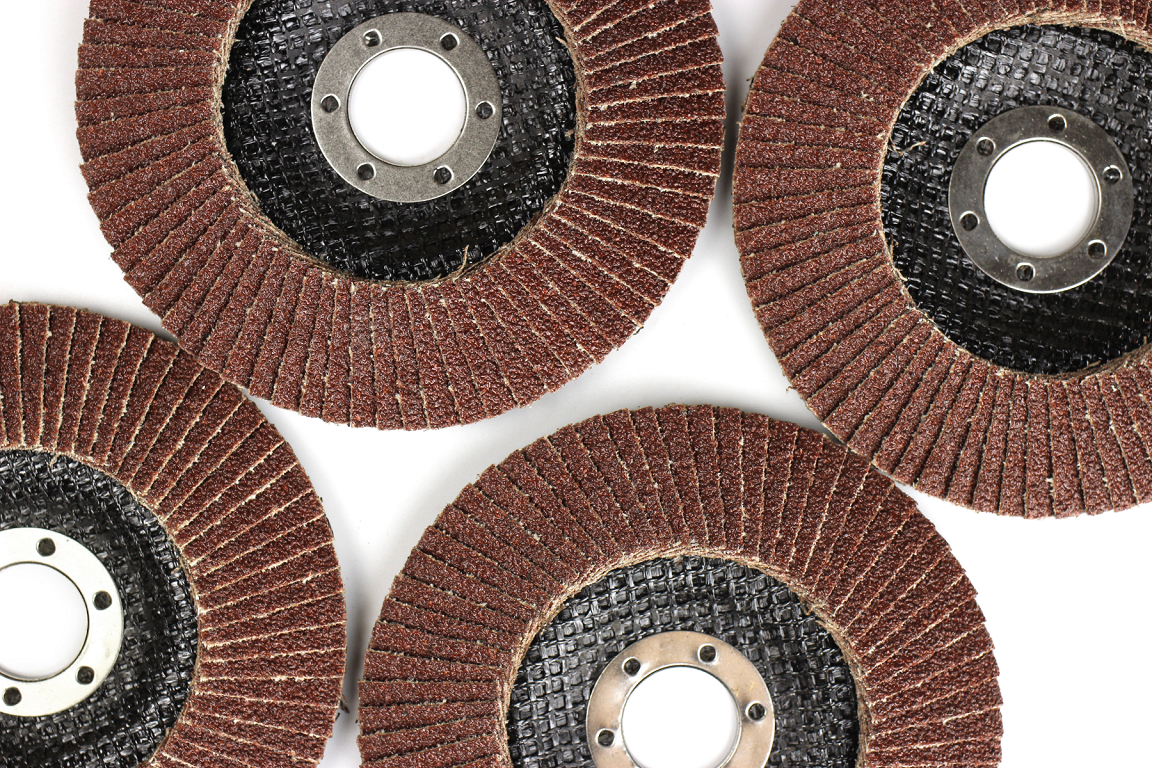

What to consider when storing and transporting grinding discs? / Day

Environmental conditions and temperature fluctuations

Grinding discs are sensitive to moisture and temperature changes. They should be stored in a dry place with a stable temperature, avoiding direct sunlight and the risk of freezing. Large temperature fluctuations can cause cracking or deformation of abrasive material. It is recommended to provide the storage space in the relative humidity range from 45% to 65% to maintain the technical properties of the materials. Incorrectly stored discs can also lose their adhesion with the base, affecting their performance.

Proper Position and Support

The discs should not be stored directly on the floor or squeezed under heavy loads. They should be placed horizontally on a flat surface or on special shelves that support the entire disk area. If the discs are hung or based solely in the center, it can cause their bow or cracking. The storage position should eliminate any mechanical tension that could deform grinding disc form. Special attention should also be paid to the fact that the discs are not too closely at each other, as this can pose a risk of mechanical damage.

Safe transportation and packaging

When transporting discs, it is important to use a protective packaging that reduces the effects of vibration and shocks. Each type of disc must be packaged according to its size and shape. The discs should not be transported open or accompanied by heavy details that can cause damage. A well -organized and thought -out type of transportation helps maintain the quality of the products and ensures the user safe. During transport, it is also advisable to use labeling with information on the fragility and storage conditions of the product.

When storing and transporting grinding discs, both technical requirements and security aspects must be met. The high -quality disk storage process not only extends its lifetime, but also provides constant grinding efficiency. By carefully evaluating and implementing these principles, it is possible to increase the level of occupational safety in the production process. Responsible treatment for storage and transport allows the full use of the potential of abrasive materials. In the end, it also affects the overall quality of production and cost efficiency.