Robots solve e-waste problems

Right next to the historic German city of Goslar, an industrial complex is spread, which receives endless flow of discarded electronics. Upon arrival, electronic waste is carefully prepared for recycling. Electrocycling is one of the largest revications for electronic waste in Europe. There are up to 80,000 tonnes of waste of all kinds and shapes each year.

Despite the impressive number of machines, more than half of the employees at the location manually prepare the discarded recycling equipment. The waste received is sorted and removed by batteries that are dangerous due to possible fire and a major challenge in recycling e-waste. « There are more and more devices, they are getting smaller, all of which contain lithium batteries, some of which are permanently installed, welded or glued, » said Electrocycling CEO Hannes Fröhlich. “During the daily disassembly of these devices with hammer and pliers, it is not a dream work. I think we can be better. «

Some of these strenuous tasks could be done by robots. However, the problem is that any change in the product or process must be restructured by hardware and software. This, however, can be expensive and time consuming. In order to solve this issue, the ReconchyCle research initiative, financed by the EU, managed to automate the process with robots that can reconfigure themselves for various tasks.

A new area for robotics

Researchers from Slovenia, Germany and Italy participated in this challenge at the Jozef Stefan Institute (IJS) between 2020 and 2024. The team developed flexible robots with support for artificial intelligence that can remove batteries from smoke detectors and heat meters for radiators.

The product found in most households should be replaced every five to eight years, with large amounts of waste. “The main challenge is many versions of each device. Just think how many different remote controls exist, « explained Dr. Aleš Ude, Head of the Department of Automation, Biocybernetics and Robotics at IJS, which coordinates the Reconcycle Research Group.

In industrial environments, robots are usually programmed for one specific task, repeating exactly the same set of movements in a predictable environment. Instead, researchers have decided to create a robot that can adapt to many different tasks using state -of -the -art artificial intelligence. « We wanted to expand robotics, introduce robots where there are none, » Ude said.

A growing problem

In cooperation with Electrocycling, the International Research Group has created a flexible robotic work cell. It is a workspace consisting of at least one robot, its tools and equipment and a controller. The novelty is that the closed system adapts independently to various tasks through the complex software driven by artificial intelligence and modular hardware that can be quickly reconfigured. It also uses soft components such as softthand, a man -like hand that can handle objects very carefully.

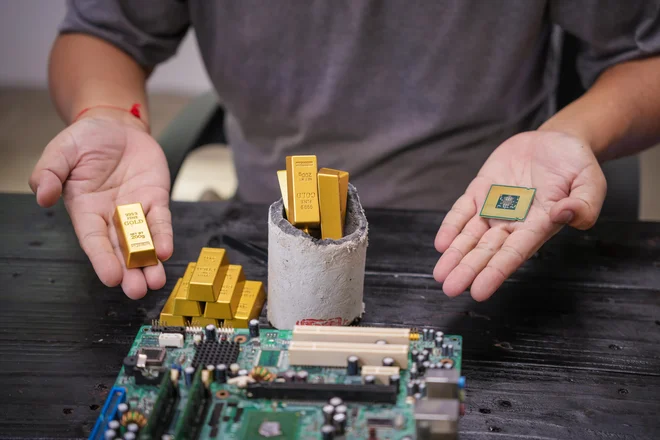

Electronic waste is a real golden cave: estimates Ton e-waste contains at least ten times more gold than the tone of ore from which gold is obtained. Photo: Shutterstock

Security features are also available, such as participating robots and emergency stop buttons. According to Udet, international cooperation was crucial in providing appropriate expertise. « Robotics is very interdisciplinary, so it is difficult to find the right partners in a single country. »

Fortunately, the new robots came just at the right time, as the amount of e-waste generated continues to increase. Almost five million tonnes are generated every year in the EU, about 11 pounds per capita. However, less than 40 percent recycled, the European Parliament warns.

According to the United Nations, 62 million tonnes of e-waste were produced in the world in 2022 alone, which would be sufficient for half a million 40-ton trucks. It is even more worrying that the amount of e-waste increases five times faster than the recycling amount. The EU seeks to reduce the amount of e-waste with a waste electrical and electronic equipment directive that sets out standards for collecting and recycling.

The work of the team led by dr. Ude, it is also coordinated with the EU digital strategy, which promotes the use of artificial intelligence in production for greater efficiency and assistance in achieving climate neutrality by 2050.

Scattering money

E-waste also have serious economic consequences. According to the United Nations World Monitor, we lose € 84 billion every year because we discard valuable metals such as copper, iron and gold instead of reused.

In an industrial environment, robots are usually programmed for one specific task, repeating exactly the same set of movements in a predictable environment. Photo: Shutterstock

At Electrocycling, 80 percent of e-waste « turns » into raw materials such as iron, zinc, gold, silver and palladium, together they extract about 35 different materials from waste. « People need to understand that these are not only waste, but also of the raw materials that need to be recycled and in circulation, both for economic efficiency and due to reducing carbon dioxide emissions, » Fröhlich warned. With new technology, they can be even more efficient and Fröhlich sees many options in it. « I was surprised by how far technology and artificial intelligence came, » he said. “They have even created a human hand for the robot.” Learning hopes that he will continue to work with Electrocycling to further improve e-waste solutions. Of course, flexible robots have the potential to cope with the changing environment in other areas. The Slovenian researcher also stressed that by further development, similar robots could take care of general household chores or help caregivers in nursing homes. « Robotics could be of great help in these areas. »

—————————–

The research mentioned in the article are funded under the EU Horizon program. The article was originally published in Horizon magazine, an EU journal for research and innovation.